Sticky Threads

I’ll be honest; I’m writing this article largely so I can quote Tom Hill’s Stuck Pipe booklet. T H Hill has a long history of providing training to drilling engineers, but not everything we’ve done has maintained enough interest to remain in the catalogue, which is kinda sad. The upside is that I, the bespectacled archivist, can go searching through our library and find gems from the past.

Stuck Pipe: An unfortunate situation wherein your drill string is attached to one more fixed object than is temporarily convenient.

The course went through many different sticking mechanisms, thinking about how they work and what you can do to avoid them, and the book was meant to be a companion reference for it. I never got to take the class, but I can pull goodies out of the paper trail.

For instance, this book has what appears to be the early version of the stuck pipe material that first got written into DS-1 Volume 2 in the Third Edition (it’s still there in the Fifth). In DS-1 the treatment of the actual mechanisms (differential sticking, swelling shales, hole packoff, oh my!) is brief and, sadly, a bit more formal. It appears that I’m not the first person at this company to write with equal measures of science and snark.

In spite of all our admonitions, you’ve got yourself into the same strait as the parent whose child runs away to become a radical environmental terrorist. In other words, someone (or something) close to your heart has formed an obsessive, unnatural and unhealthy attachment to the planet. Now you want to know how to get free and how much you can pull, torque and pump on your drill string in attempting to get it free.

(A key and critical distinction between my writing and Tom’s is my righteous zeal for the Oxford comma.)

DS-1 is fundamentally a structural failure prevention book, though, so the standard puts a little more focus on what happens to your load capacities when the drill pipe has developed that unhealthy planetary attachment.

Tubes are easy: a tube is a tube, and you just have to know the loading conditions to figure out when stuff will come flying apart. That might include pressure, torque, and tension (see the comma?) all at the same time, but we’ve got charts for that, and it’s the same as the charts for drilling, so we know how it goes.

It’s connections that get wonky.

… in the case of tension and surface torque, where surface torque exceeds makeup torque, tool joints will behave differently depending on the sequence in which the two loads are applied. If this seems confusing, believe us, it is. It was, however, explained by Baryshnikov, et al …

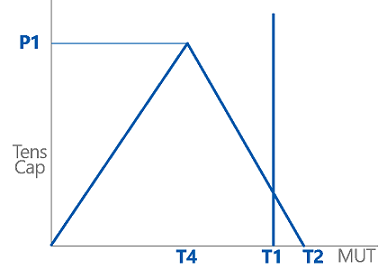

Remember how we’ve noodled about the way stress gets built into your connection? You apply a makeup torque, which pulls the pin into the box and compresses the seal area. String weight, then, increases the pin tension and decreases the box / seal compression, and there’s a pretty triangle graph we use to describe when and how your connection gets boogered up.

But! The load-application process in that overwrought thought experiment of mine was always “stab, spin, bump the shoulders … apply just a little bit of torque.” (Yes, I just quoted my own durn article, and I’m feeling quite smug about it.) It turns out that the order of operations makes a difference.

Makeup torque then tension is one thing; tension then makeup torque is an equine of an alternative tincture.

You can imagine why that might be the case—if you pull on the connection, that’s going to increase the tension on the threads but decrease the compressive stress on the shoulder. That doesn’t happen equitably—it depends on the exact geometry of both sides and how they interact. So mebbe it takes more torque to make up the threads if tension is applied, mebbe it takes less, you just never know. (Erm, until you do the math. Then you know.)

The math now includes another term called “T3” by API. Wait, what were the other terms?

- P1: The tensile force that the pin can carry, and the biggest possible tensile load capacity of the connection.

- T1: The torque it takes to compressively smush the box counterbore area, sans tension.

- T2: The torque it takes to yield the pin neck, sans string tension (although the failure happens because of tensile stress from pulling the pin into the box, you remember).

- T4: The peak of our triangle, a special makeup torque where string tension causes pin yielding and shoulder separation at the same tensile load.

Right, ok, so T3 is … “torsional load required to produce additional makeup of the connection when the shoulders are separated by an external tensile load on the pipe that produces yield stress in the tool joint pin,” according to API RP7G.

Yeah. (cough) Let’s try again.

“… the point [T3] represents the overtorquing or backing-off overcoming the friction moment in a connection previously tightened with a makeup torque equal to [T4] and then submitted to the axial load [P1] which produces shoulder separation and pin yield.” (From IADC/SPE 27535, the Baryshnikov et al paper mentioned before; I altered the names of the terms for consistency here.)

Boy, this is confusing.

What all this gobbledygook refers to is the order of operations. Our standard connection combined load curve presumes that you’re not a psychopath, and you don’t try to make up a connection with the weight of the string hanging off it. As such, the only stresses in the threads and shoulders—where the friction comes from, which is where most of the torque comes from—are the stresses you’ve put there with makeup torque.

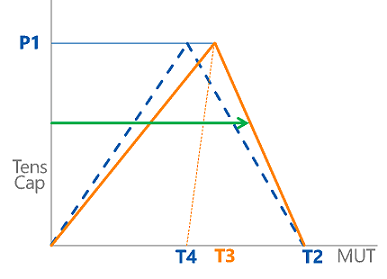

The question Barry’s asking (his name is Anatoly Baryshnikov, but I can call him Barry, right?) is: how much torque does it take to cause movement in the threads if there’s already tension applied?

As we apply tension to the connection, there are two competing effects on the friction in the connection:

- The string tension increases the tensile force being carried by the threads, which increases the frictional resistance in the threads. More string tension, then, means it takes more torque to make up the connection by an additional amount.

- The string tension decreases the compressive force on the seal surface, which decreases the frictional resistance there. So more string tension means it takes less torque to make up the connection an additional amount.

Who wins the battle of the frictional resistances?!?

Depends. That’s what “T3” is about. If T3 is bigger than T4, then it’s more difficult to make up the connection when tension’s applied. If T3 is less than T4, then it’s easier to make it up.

I’m thinking I need a picture.

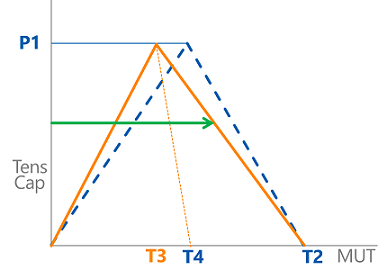

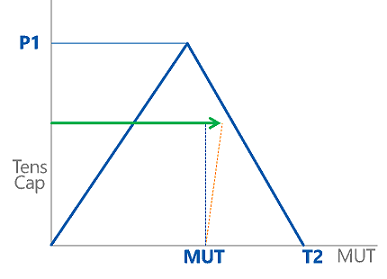

We start with our now-familiar connection combined load curve, a triangle with the tippy-top at a makeup torque of T4 (dotted blue lines). Since we’ve decided we’re concerned with tension-then-makeup as opposed to makeup-then-tension, we have to adjust by moving the triangle’s summit over to T3 (orange lines). Now in order to know how much downhole torque my connection can handle, I start at my hanging tension on the left side and read across until I get to the shifted pin-yield line (see the green arrow, no relation).

Notice that in the case above, T3 is bigger than T4, and that makes the makeup required to yield the pin bigger than it would have been normally. If T3 is smaller than T4, as below, the result goes t’other way.

In fact (!!!), the slope of that thin, dotted, orange line in both graphs represents who wins our friction battle from before. As we send the pipe down the hole, the tension will alter the amount of torque it’ll take to make up the connection downhole.

“Whoa!! Grant! Doesn’t that mean that we might LOSE TORQUE CAPACITY if T3 is LESS than T4?!?!”

Yes, my excitable (and imaginary) friend, that’s exactly what it means. If, for a given connection, T3 is less than T4, tension will cause your drilling torque capacity to be reduced at a rate proportional to P1/(T4-T3) (rise over run, baby). You’ll make up the connection to 20,000 ft-lb at the surface, but you could overtorque it downhole at only 19,000 ft-lb.

“Why have you never, in all the blather you’ve given us about connections, mentioned that critical piece of information!?!”

Because, for most typical API connections, T3 is bigger than T4. Usually (though not universally, I’ll admit) when you make up an API connection to 20,000 ft-lb, it’ll take 21,000 ft-lb to actually overtorque it downhole. So we, along with most of the rest of the planet, have elected to ignore that little mathematical nugget, understanding that most of the time we’re being conservative.

You know how much I love this crap, working through applied mathematics to describe the operational engineering problems we encounter. Still, I’ll end with the very picture of wisdom given in the Stuck Pipe Handbook:

It’s far easier and more economical to not get stuck than it is to get not stuck.

Understanding how your capacity changes is good, but avoiding the situation entirely is obviously better. So work on your preparation, your planning and contingencies, and remember …

“… one of the most evident, axiomatic, and oft-repeated phrases in the oil patch:

It’s the mud engineer’s fault!”