Storytime With Uncle Tom

A long, long time ago (the 1980s) in a galaxy far, far away (offshore Louisiana), our intrepid heroes (the casing crew) are pinned down by the enemy, pondering the options for escape, or for glory …

I don’t think I can keep that up.

They were running 9-5/8", LTC casing, and it was not going well. Very often the Torque-Turn chart would be bad, and what you’re supposed to do is break out the connection, clean it, visually inspect it, re-dope it, and try to make it up again.

What actually happened: they broke out the connection with great difficulty, smoke and swear words drifting through the air. The threads were a mangled mess, so “clean, inspect, and try again” was laughable. Instead, they had to pull that joint, requiring them to break out the connection below. That connection was then also messed up, so they had to pull another one …

One step forward and two steps back is no way to run casing, especially when drilling the hole section they were now trying to case off had been a … challenge … due to formation instability and sticking. So the company man, with arms waving and epithets flying, instructed the crew that there would be no more pulling joints. If a connection was bad, that coupling would be delicately split off the pipe by the welder (not sure how delicate you can actually be with a cutting torch, but anyway), and a new coupling would be floated on. (The new couplings had been choppered out to the rig.)

Interesting fact: the floated-on couplings never had makeup problems. Hm.

With 84 joints in the hole, that is, when they were about to enter the open hole (finally), the operator threw up their hands and hit the abort button. With all the time it had taken (like 2 and half days for just 84 joints) and no circulation in that time, they were afraid of what would happen when problematic casing met problematic formation. It seemed like get stuck, can’t fish, lose the hole was a very real possibility. Instead, they elected to pull the whole string, use the drillstring for a cleanout run, and try again with a new string of casing.

Now, look, these are office people that make this decision. In the office, they gather around a conference room table with stale kolaches, they seriously discuss the options and the ramifications of their choices, and they plan out what happens next. After deciding to give up on this casing string, they push back from the table and wander into the hallway talking about what’s for lunch.

On the rig, that crap still has to actually happen. Do you remember how hard it was to run the casing? Hm? They had even more issues getting the freakin’ connections loose. The, let’s call it “irritated,” company man basically watched one connection lock up while they were trying to back it out and said “nope.” He told the casing crew to rig down their tongs; we’re not even going to try. He called the welder back up to the floor and told them to cut the string apart. (Hand on a Bible, man, it happened.) They’d cut off the tube above the coupling while it was sitting in the slips and then lay each joint down. After the whole string was out of the hole, the welder then went down to the racks and lopped off the couplings from the rest of the lower tube, leaving a pile of couplings with power-tight pins in both the mill and field ends.

That pile was sent to T H Hill Associates, Inc for analysis.

Now, look, this was a monumentally bad day (few days, really) for the operator … but … oh man, was it exciting for us! This is the failure analysis of a lifetime! It’s the perfect data set! It wasn’t just one galled connection (something we get pretty regularly)—it was 84 different connections, a statistically-significant sample size! The connections had never been backed out, so there’s no question about whether the damage happened on the way in or the way out! There were Torque-Turn charts for everything, with 47 of them traceable to the specific connections you could put your trembling-with-excitement hands on! (Yeah, I know, the traceability wasn’t ideal, but we did the best we could.) Within the larger sample there was a smaller sub-set of choppered-in connections that didn’t have the same problem even in the same rig conditions! And then there was the second casing string that had run with no issues, with Torque-Turn charts! I can’t stop typing exclamation marks!!!!!

Deep breath.

Ok. Let me walk you through the important findings from the failure analysis of the century here.

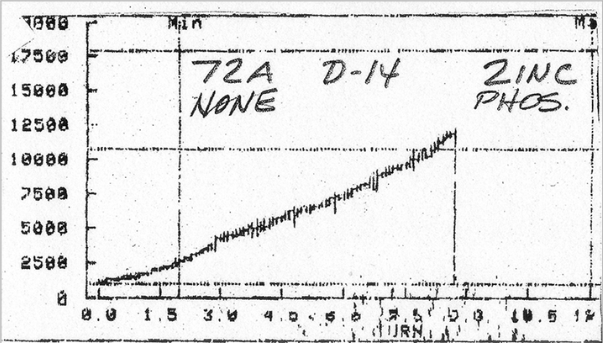

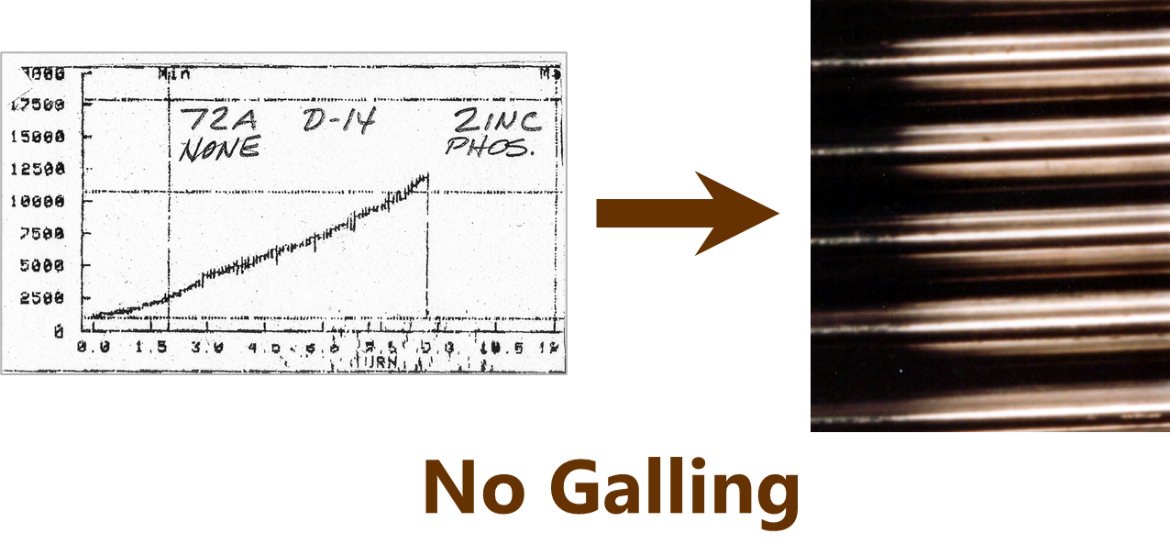

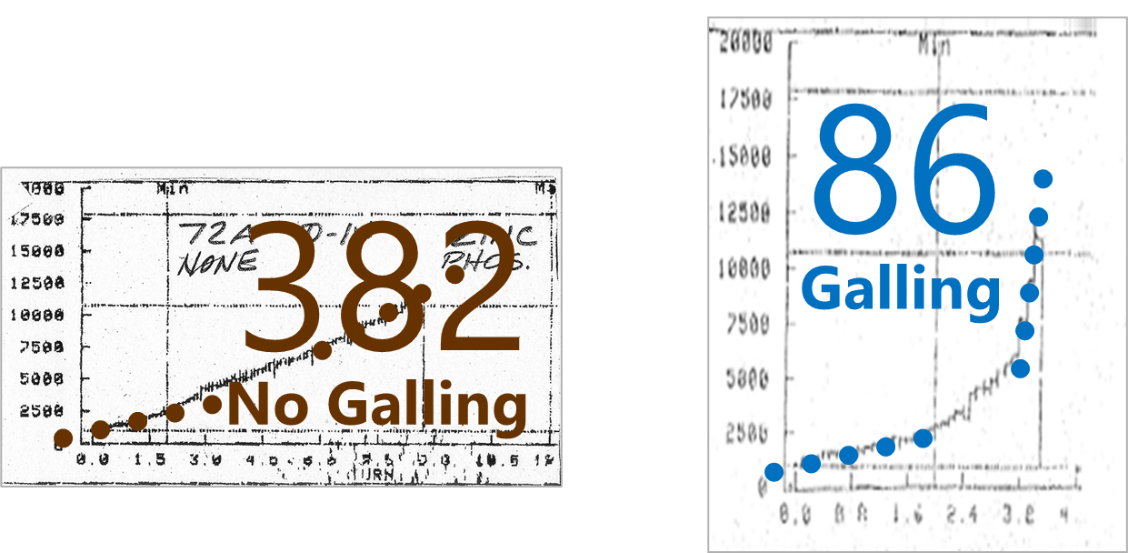

We’ll start with Torque-Turn charts that were actually traceable, that is, the 47 charts that we could tape to the couplings that made those charts. Reading through the charts, we realized we could pretty clearly distinguish two different categories of chart. Chart Category A shows a slope that rises slowly over the whole makeup chart, with the ending slope no more than 25% bigger than the starting slope.

Chart Category B shows a slope that suddenly spikes up toward the end, like so:

(No, no, no; don’t get ahead of me. You know exactly what’s happening in Category B, and you’re right, but we’re being purposefully, scientifically dumb. Right now, the evidence that I have is just that the pattern of slopes is different between Chart Category A and Chart Category B.)

So now we have two piles of Torque-Turn charts: Category A, with it’s easy-like-Sunday-morning slope, and Category B, with it’s another-brick-in-the-wall slope. We pick up one of the Category A’s, we walk out into the laboratory (you have to say that “lab-OR-a-TOR-ee,” by the way), we find that particular connection, and we cut it apart to examine the threads.

Those threads are squeaky clean (well, after you clean the dope off, obviously) with no damage or issues. That turns out to be true for every one of the Category A charts—none of them have any significant galling damage.

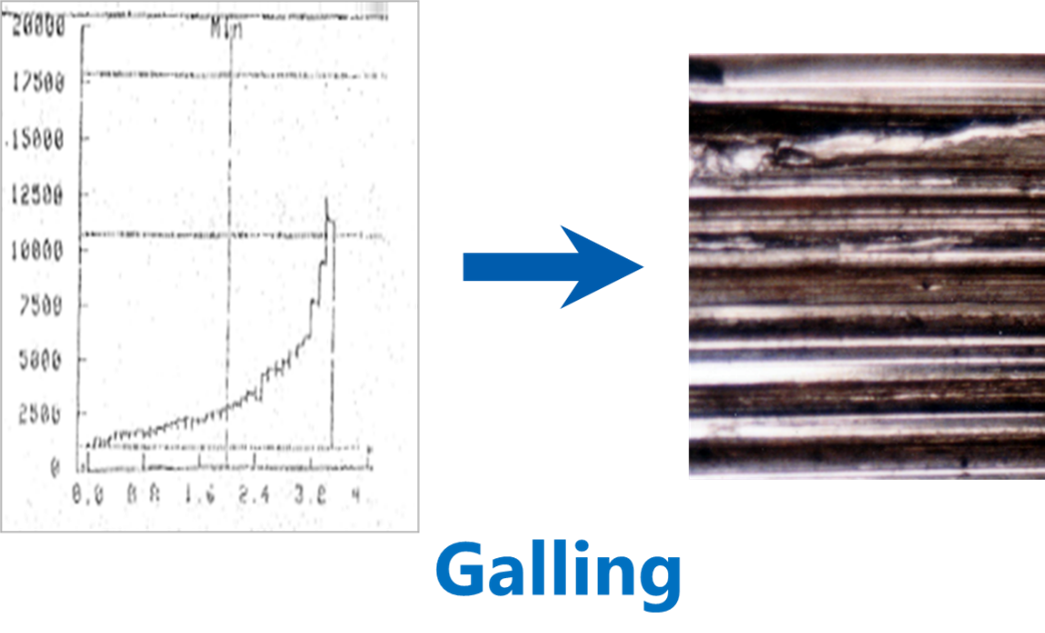

Next we pick up a Category B chart and cut open that connection.

This time the threads are thoroughly boogered up, with galling and damage throughout. That, too, was the consistent pattern for all the Category B charts.

Every. Single. Time.

Look, I know you expected that; the “Category B” chart is obviously a galling pattern for an LTC connection—it looks like you whack a shoulder and the connection doesn’t have a shoulder! But! By being purposefully dense, we’ve now proven something more objective: we can look at the Torque-Turn chart and tell, with no exceptions, whether or not that chart represents a galled connection or not.

That means that I can now expand my analysis to all 468 Torque-Turn charts that I have available. Even though I’m not entirely sure which chart goes with which connection, I know just from the chart whether or not the connection galled while making it up.

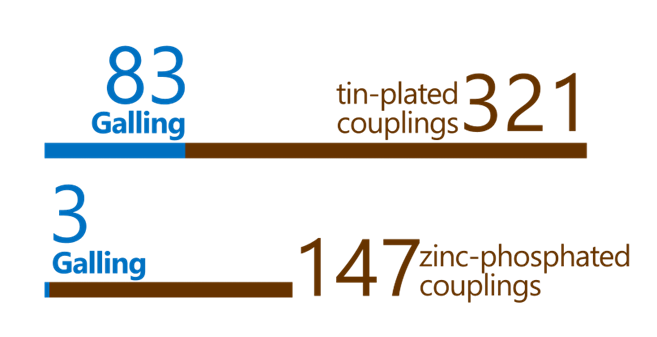

At this point I can make one more distinction for comparison’s sake. Some of the connections studied in these two strings (plus extras) had couplings that were treated with tin plating; some of the couplings had been zinc phosphated. Both of those treatments are intended to minimize the chances of galling in the threads, so it’s worth looking at which one was more effective.

Of the 321 tin-plated couplings, 83 of them—or a whopping 26%—galled. Of the zinc-phosphated couplings, only 2% galled. The conclusion (and I quote): “Tin-plated couplings are 10–15 times more likely to gall than zinc-phosphated couplings.” The first, troublesome, string was tin-plated. The couplings choppered out in the throes of it which never had makeup issues—phosphated. The new string that ran without problems—phosphated.

Mic drop.

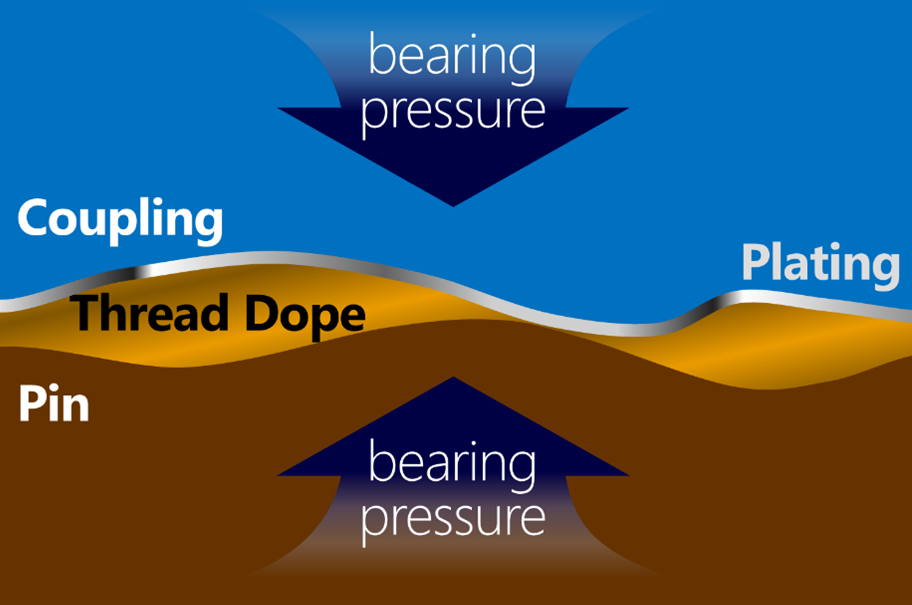

Them’s the facts. Still, it helps to visualize some of the science. At a really small scale we have two surfaces pushing against each other while also sliding past each other. There’s thread dope in between those surfaces, and there might be tin plating between the surfaces.

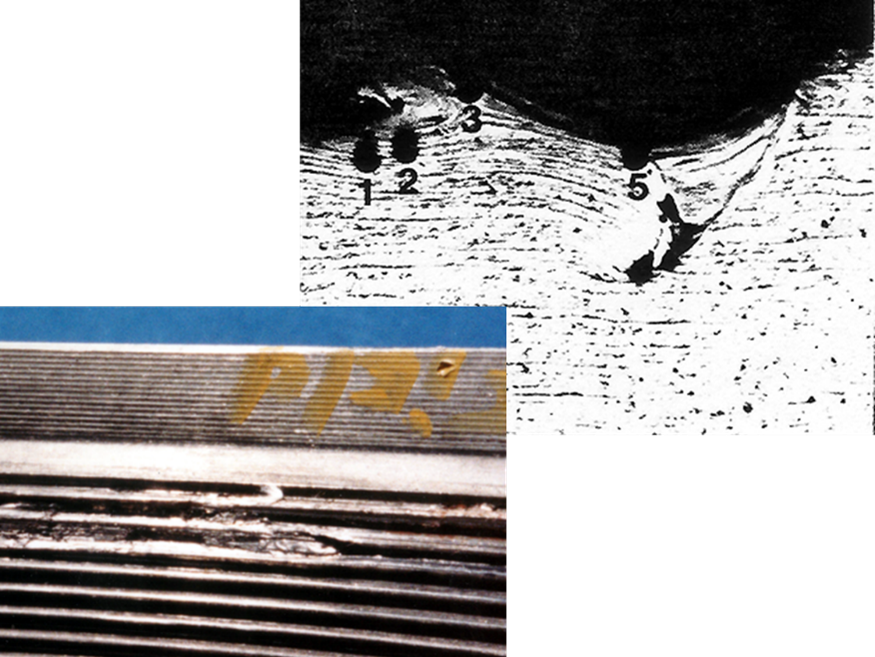

If all those lubricants are wiped away at a spot, leaving bare steel pushing against bare steel, the molecules at the two surfaces forget which side is which and start jumping back and forth. That means there’s really not a surface anymore; the two sides are “cold welded” together at that little spot.

As the connection continues to turn, that cold-welded spot then plows through the surfaces, causing even more of a mess. In fact, in some instances you can see the two different sides that became stuck together, like the pin thread stuck to the coupling in this optical metallography picture:

Galling, then, happens when you get steel-on-steel. That is, in fact, the purpose of thread dope—with thread dope in place you have steel-on-copper-on-steel (or steel-on-zinc-on-steel, or steel-on-teflon-on-steel, or whatever the solids in the dope are), preventing the cold-welded spots that initiate galling damage.

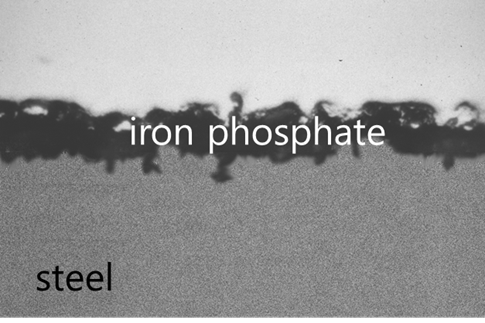

This is where phosphating comes in. That zinc-phosphating (it can also be manganese phosphate or some combination) consists of dumping your coupling in a hot acid bath like you’re trying to make the Joker. The acid etches into the steel surface, leaving behind a very thin layer of iron phosphate (it’s a dull gray color, you may have seen it on new connections).

That phosphate layer is nice, but honestly it doesn’t provide a whole lot of help keeping the steel surfaces separate. It’s thin, and it’s brittle, so it goes away pretty quickly. The real reason phosphating is so helpful is what it does to the steel underneath. Instead of a smooth, slick surface, now we have hills and valleys and pockets. The thread dope you put on isn’t squeezed out from between the surfaces, it stays in the pockets—and if the dope stays put, then the dope can do its job.

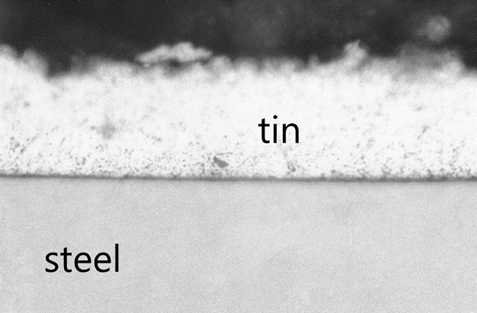

No so with tin plating. The tin that is electro-deposited on the steel surface is a thicker layer, but it never really bonds to the steel. (That’s not a comment on the quality of plating—at this small of a scale, there’s no chemical mechanism for the tin to grab onto the steel, so it just doesn’t really stick.)

With no chemical bonding, and no mechanical teeth, the thick tin plating slides right off the slick thread surfaces. That puts steel on steel, and makes the connection more likely to gall.

These are pretty strong statements—tin plating is much less effective than phosphating as an anti-galling treatment—but we have the data to back it up. Come to think of it, you have the data to back it up. Every premium, proprietary casing connection you’ve ever seen has been treated with … da dada DAA! Phosphating! As much as they charge for those things, they could plate them in gold if it would work. But premium connection designers and manufacturers universally use phosphating as the treatment that will get them the best results.

(This is the internet, so I feel the need to qualify the universal statements up there … no, you know what, the feeling passed. Let’s move along.)

Now my favorite part—the rest of the story. There were a few hints along the way that I, Grant Pettit, was not immediately involved in this particular failure analysis. People haven’t really run LTC connections in an offshore well in a really long time, and in 1986 I … couldn’t read yet. This is Tom Hill’s story (from T H Hill Associates, ya know?)

After the analysis was done Tom presented the report and findings at a meeting between him, the operator, and the casing supplier. Tom’s conclusions were clear—tin plating bad—and backed up by solid data and logic. Still, the supplier (naturally) didn’t buy it. They insisted that tin plating works fine, they’ve been doing it for years. The problem must have been at the rig, and the second string went fine when they (silently) fixed whatever problem they had during the troublesome run.

The operator jumped in at this point. “Wait a minute … when we split the couplings, we saw a bunch of damage on the mill end connection, too. The rig didn’t mess with those connections, but they’re also galled.”

“No, no,” says the supplier, “the daily reports mentioned that most of the time the couplings started to turn when things went south.” True, the reports did say that, and it often happens that the mill end starts to make up if the rig end locks up from galling. “Mill end or not, the galling happened at the rig.”

“So you’re telling me that the rest of this casing string, the stuff that was never run or made up (that we’ve quarantined this whole time), will not have any galling underneath the bucked-on couplings?”

“Correct.”

At that the operator turned to Tom and did his best Jean Luc Picard impression. “Alright, make it so. Go pick 5 casing joints out of that group and cut up the couplings. Let’s see if they’re galled.”

Tom clicked his heels and headed down to his beat-up jalopy of a car to drive to Lafayette, Louisiana where the pipe was. He shows up at the pipe yard, walks out into the yard itself … and is struck by the sheer size of the pile of casing.

He doesn’t have any X-ray glasses handy to see what’s going on in those connections, so he picks out 5 joints randomly for them to cut off the couplings and dump them into his trunk, out of the big stack of casing.

There’s really a lot of casing left over …

The problem with that drive to Houston is that it’s 4 hours long, which gives you plenty of time to think. The problem with Tom is that he tends to get a little wound up when he thinks too much. So he starts doing some mental statistics … 26% of the tin-plated couplings were galled, which is a huge amount, but it’s only roughly 1 in 4 overall … crap, the percentage might be a little smaller for the mill end connections because they’re made up in a shop … if I pick 5 out of that big population, what are the chances that one of them is galled even if I’m totally right …

He realizes he’s white-knuckling the steering wheel, so he decides to calm himself down with some deep breathing and a promise. If at least one of these couplings is galled, he thinks, then it’ll be great for my business. I’ll be the preferred failure analyst for this operator and maybe some more once people talk about it a little bit. That will lead to more good things, so if at least one connection is galled … I’ll buy me a new car.

With a little more deep breathing, he pulled into the machine shop in Houston. He brought the five couplings to the saws, and they cut them apart and laid them out for him to inspect. Out of the five couplings he chose … all five were galled.

And that, kids, is how Tom Hill got a new Mercedes.