DS-1® Standards

Fifth edition available now

Standard DS-1® is a global, industry-adopted standard for drilling and completions technology. Bureau Veritas developed the first edition of Standard DS-1® in 1992 to address the lack of industry standards for downhole drilling tools. As the industry developed and changed, Standard DS-1® was updated in second, third, and fourth editions based on our experience and our sponsors’ input. Bureau Veritas continues to keep pace with our industry, and we are proud to release the fifth edition of Standard DS-1® in August 2020.

The six-volume set addresses the following:

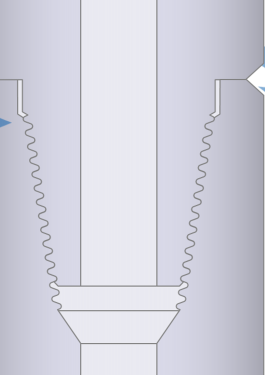

Volume 1: Specifications for newly manufactured tubular drilling products

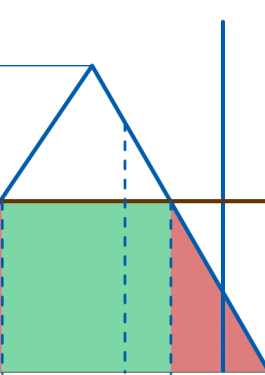

Volume 2: Risk-based design resources for prevention of drill string failure

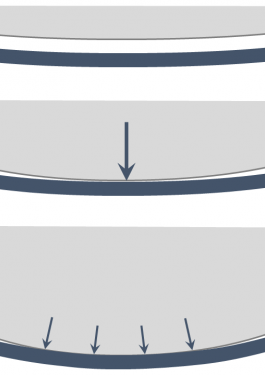

Volume 3: Inspection of used tubular drilling and completions equipment

Volume 4: Specialty-tool maintenance (inspection, assembly, and testing) procedures

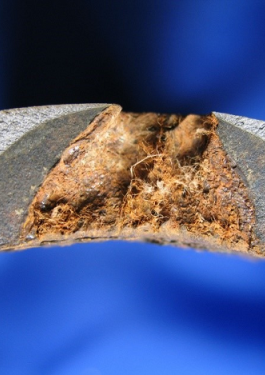

Volume 5: Inspection of drilling bits and reamer cutting structures

Volume 6: Aluminum drill pipe inspections (Now included in DS-1® 5th Edition)

Standard DS-1® is comprehensive, technically sound, easy to implement, and flexible enough to adjust to a changing industry. Our in-house engineering team conducts extensive research to update and maintain Standard DS-1® as the leading failure prevention resource in drilling and completions. With our many years of experience in analyzing drill string component performance, Bureau Veritas is uniquely qualified to provide recommendations on drilling operational procedures, no matter the complexity.

Order the DS-1® 5th edition now

Related Services

Related Articles

Related Offers:

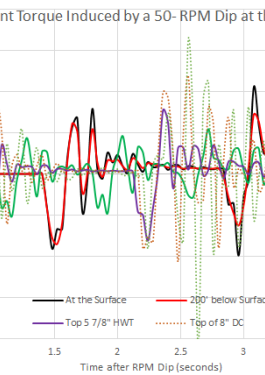

New Technology Development

With our vast library of historical data accumulated over more than 35 years of providing engineering, QA/QC services, and training to the drilling industry, Bureau Veritas is uniquely positioned to be able to develop a full spectrum of services to drilling and well completion operations. Our engineering team is composed of personnel specializing in all aspects of these operations who can bring their experience to develop new services to the industry. We will continue to pioneer and develop other technologies in our pursuit to provide premium services to the industry.

DS-1® Acceptance Criteria App

We have an electronic version of Volume 3 that you can get, but sometimes you just need to know what’s good and what’s bad. So we’ve developed a reference app that gives you those criteria, both for iPhone® and for Android™. Check it out!

This app provides DS-1® Volume 3 reference information. Volume 3 of DS-1® is our most popular standard; it gives you the inspection methods and procedures that are so critical to the success of your projects. It also has a big list of information about the acceptance criteria—good and bad—for tubes, tool joints, and connections.

Our DS-1® app runs on iPhone®, iPad®, and Android™ devices.

REGISTER STANDARD DS-1

By registering each volume of your Standard, you will receive:

- Addendums, updates, and clarifications as they are published

- Information on future editions

The Registration Form and Registration Number are included in the front of each volume. You may complete the form in your book, or download the Registration form, and email the completed form to ds1@bureauveritas.com.

Sponsorship

Over the past twenty-five years, the Standard DS-1® has evolved from a simple drill stem inspection standard to the global reference for manufacture, design, and inspection of drill strings and specialty tools. As drilling technology changes, Bureau Veritas is committed to providing the best in technical standards to service the industry.

We are continuously seeking other industry leaders to be a part of future DS-1® development to guide the content of the Standard.

Each sponsor receives:

- A seat on the Steering Committee which oversees development of the standard

- 15% discount for public training courses for the latest DS-1 edition

- Discounted price on purchase of volumes

- Prominent recognition at the front of each volume

For more information, please contact us at ds1@bureauveritas.com.