Learning to Count

We are all children of our upbringing, and most of my career has been in upstream oil & gas drilling. That means there’s lots of ridiculous jargon I know about (there’s about three different things that might be called “idiot sticks”), a surprising number of my explanations start with “that’s because back in the 1960s …”, and most of the people working around me have war stories about company men (“Do you know how much I’m paying for this rig every minute?”).

It also means that T H Hill does “3rd party monitoring.”

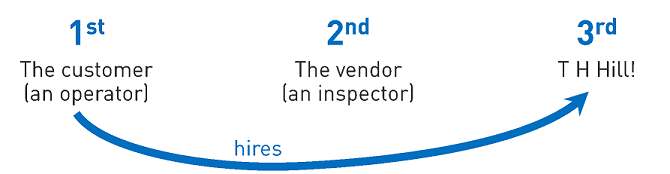

Here’s how that works: Party #1 is the operator, the end customer for just about everybody in the drilling world. Party #2 is the company that the operator hires for a product or service—right now we’re likely talking about an inspection company that’s inspecting some component that’s going into the operator’s well.

Our operator—let’s call her Natalie—knows that her success depends on the vendor supplying high-quality tools and services. Nat also knows that her procurement people have beaten them down to the lowest price possible, then asked for a “temporary” discount. Nat-dog holds those two truths in her head for a bit, and starts to get a little nervous.

So we do things like write clear standards that show exactly what we expect the inspectors to do. Natalie wants to really hold them to it, so she sends somebody to watch them who knows inspection and intimately understands what the standard requires. That company is Party #3.

Back in 2012, though, T H Hill Associates, Inc was acquired by Bureau Veritas. BV is a France-based company that does a ton of different things in a ton of different industries, and many of them include “3rd party inspections.” Being a little slow on the uptake, it took me a while to realize that these Europeans count differently than I do.

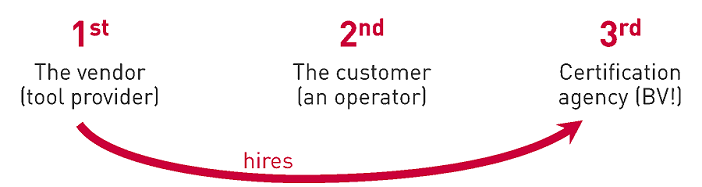

Party #1 in the typical certification scheme codified by various EU directives, is the vendor or supplier of a particular product. Party #2, then, is the end user of that product (an operator if you’re still in the energy world). That leaves the #3 slot for the certification agency again, but it’s different. Now the vendor is the one that hires us, which seems like a terrible idea—why would we be eager to tell our own customer that they’re doing something wrong?

But! The way EU-style certification works is that the 3rd party is not just responsible to their customer, they’re also responsible to the rest of the world via the applicable regulatory bodies. So while the money comes from the vendor, we’re really working on behalf of the government (or … something … you can do the poli-sci research there).

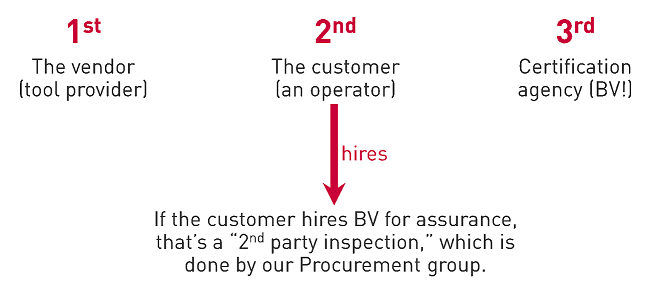

To complicate matters further, sometimes the customer will hire an outside representative to simply protect their interests. Now we’re back to the T H Hill love responsibility triangle, but in this world it’s called a “2nd party inspection” because of where we stand in the scheme. (BV does that, too, but from a different group for a slightly different set of industries.)

Ok, so what I’ve always called a “3rd party inspection” is actually a “2nd party inspection” according to this. Sheesh, next you’ll be telling me there’s no Santa Claus.

Even more complication comes when the particular work is considered. 2nd party inspections—in the EU world again—are typically not as deep. Usually the inspector is only making sure that the vendor is following their own standard operating procedures and internal requirements. There’s definitely value there (you wouldn’t believe how often you get better results simply by watching somebody do their work), but it doesn’t require a lot of qualification and expertise from the inspector.

Third-party inspectors, on the other hand, are checking to make sure that the vendor is following all the applicable requirements from public standards and directives. So the inspector needs to know as much about the product or process as the vendor does—sometimes more. That extra level of qualification (and, honestly, the fact that the 3rd party might take on actual monetary liability if something goes wrong) means that 3rd party inspections are usually significantly more expensive than 2nd party inspections.

From that angle, T H Hill monitoring is more like EU-style 3rd party inspection, because our technicians are thoroughly trained in NDT methods and the public DS-1 standard that they’re likely to be enforcing.

I had no idea counting to three could be so complex.

So which one is better, Grant? The system where the customer is the focus of all responsibility and thus pays for extra QA/QC like in the upstream oil & gas drilling world? Or the scheme where society is involved via regulatory bodies and standardized enforcement relationships?

|

It doesn’t matter, and you know it. Almost any system can work properly if the people concerned do the right things and don’t cut corners, and absolutely any system can suck otherwise. (Sorry to disappoint if you expected the answer to be “’Murica!”) What’s important, I think, is to make sure you wrap your mind around the quality of the things you’re going to use. |

“There is hardly anything in the world that some man cannot make a little worse and sell a little cheaper, and the people who consider price only are this man’s lawful prey.” |

I could quote a lot of pithy things to support this opinion (see the probably-not-John-Ruskin quote for an example), but you know in your loins that cutting costs by lowering quality is going to bite you later (maybe in the loins). You know that you are required to trust other people and other companies; isn’t it worth doing something to make sure they are actually trustworthy? Hm?